Revolutionary & Patented Nano Ceramic Technology

Easy Treatment of Engine: Restore, Repair & Protect

Nano spherical ceramic powder manufacturing,

Platinum coating technology and nano dispersion & absorption technology

developed by Korea NanoTech Institute.

The combination of Platinum coated ceramic

nano powder has great advantage for engine restoration

with endurance of high temperature, humidity, superior lubrication and

great combustibility without side-effect.

The restoring ability could be well harmonized with platinum

coated nano ceramic powder.

Our uniquely developed platinum coated ceramic is 20 times stronger than steel and Platinum is helpful for great combustibility & powerful engine.

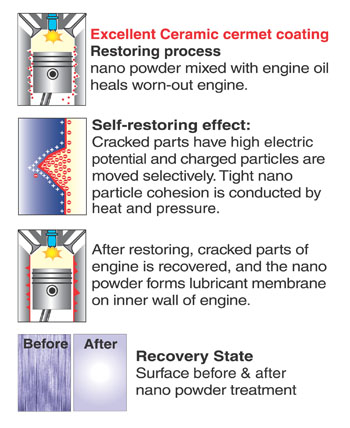

Restoring Process of Nano Energizer

Excellent Ceramic cermet coating

nano ceramic powder mixed with engine oil restores

worn-out parts of engine.

Cracked parts have high electric potential and charged particles

are moved selectively into cracked parts.

Tight platinum metallic cohesion is conducted by heat and pressure.

After restoring, cracked parts of engine is recovered and nano powder

forms lubricant membrane on inner wall of engine.

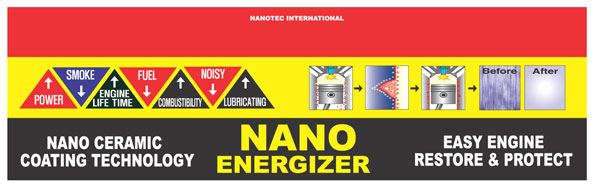

Smoother, Quieter Engine with more

Power & economical solution.

Fuel savings up to 8-21 %(up to 40% in idle mode)

5 times lowered noise and vibration levels

Restores friction surfaces and protects against wear

100 times reduction of the friction coefficient

Increased oil pressure & great combustibility

Brings engine power up to 100%

3-9 times reduction in CO and CH in the exhaust

good for the environment

safe & guaranteed

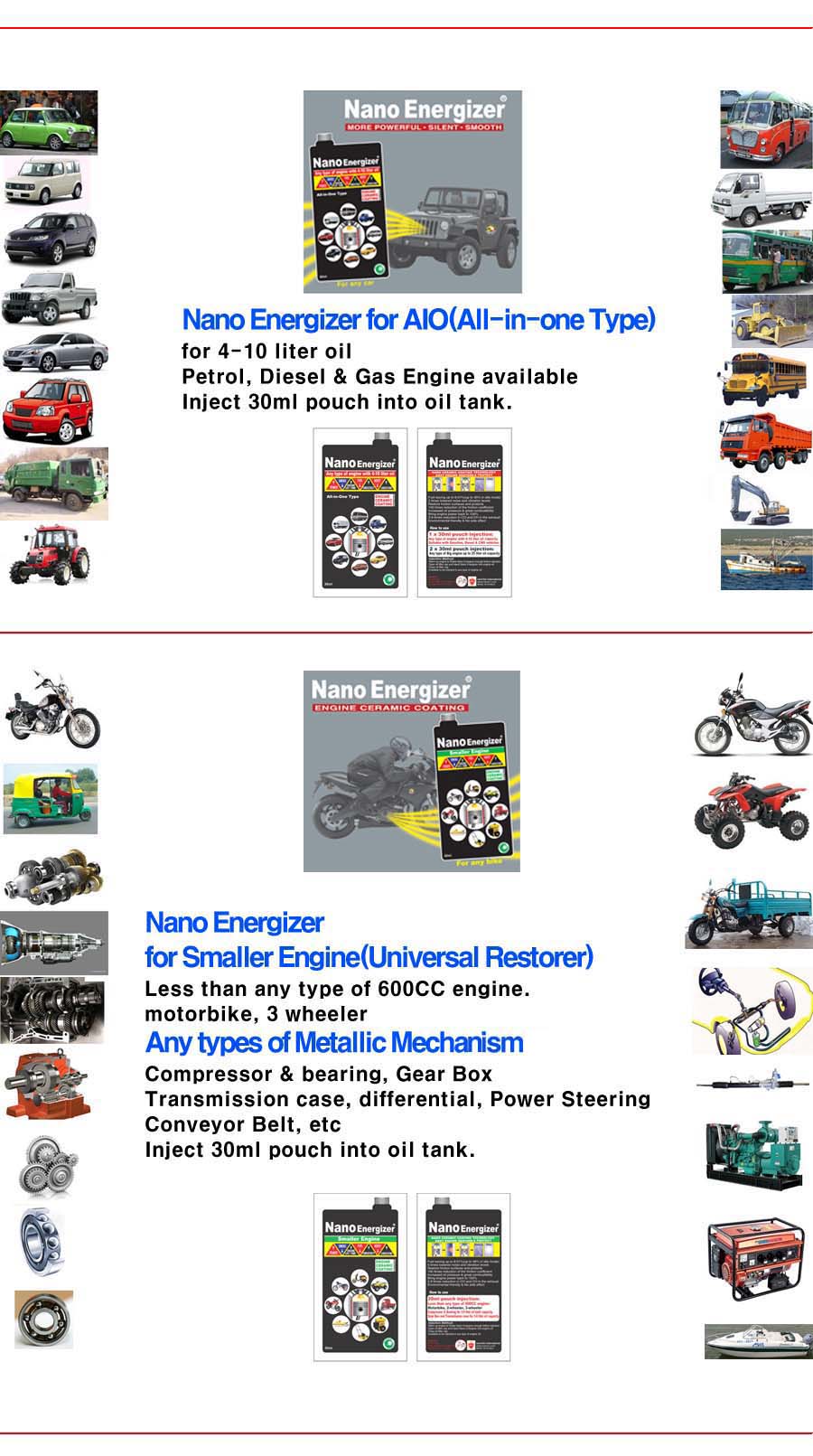

How to use

Injection Objects:

Nano Energizer recommended for automobiles at least 3,000 km of use.

The effect is better for old cars.

It can be used for any type of cars that uses mineral and synthetic oil.

Injection Period:

Injection is available at anytime, but effective period is

when engine oil is being changed.

Recommended to change Nano Energizer upon driving 30,000km.

Wear resistance of the protective coating is guaranteed

within 1year at any running.

Injection Method:

Warm up engine after change engine oil.

Shake Nano Energizer enough before injection, as subsidence may occur

for long storage.

Open oil filler cap and inject Nano Energizer slowly.

Close oil filler cap and keep idle for 20 minutes

or drive 30km.

|

After injection of

nanoE AIO, ceramic coating on engine metallic surface will be applied

from 500km - 700km run and feel great effect: power increase, |

A single Injection ensures

a powerful engine with smoother, quieter, more

economical operation.

|

|